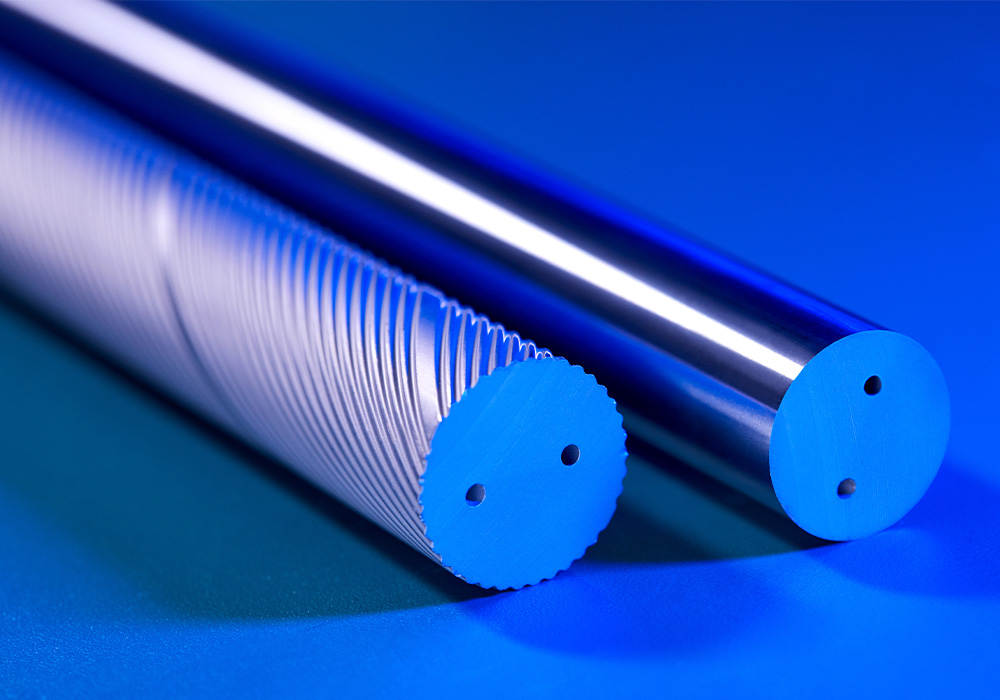

Products

Grade

Mobile phone: 17773159914

E-Mail: pm@csu-pm.com

| Introduction to Main Grades of Cemented Carbide Rods | |||||||||

| Grade | Cobalt Content | WC Grain Size | Hardness | Density | Transverse Rupture Strength | Fracture Toughness | Elastic Modulus | Thermal Expansion Coefficient | |

| Co% | HRA | HV30 | g/cm³ | MPa | MNm-3/2 | GPa | 10-6/°C | ||

| ST10F | 6 | Submicron | 92.9 | 1840 | 14.8 | 4200 | 10 | 530 | 4.9 |

| ST10UF | 6 | Ultra-fine | 93.8 | 2040 | 14.7 | 3900 | 9 | 530 | 4.9 |

| ST10NF | 6 | Nano | 94.5 | 2180 | 14.6 | 3200 | 9 | 530 | 4.9 |

| ST10C | 7 | Fine | 90.7 | 1480 | 14.7 | 4000 | 12 | 520 | 5.0 |

| ST11F | 8 | Submicron | 92.3 | 1720 | 14.6 | 4400 | 10 | 510 | 5.1 |

| ST11UF | 8 | Ultra-fine | 93.5 | 1960 | 14.5 | 4200 | 9 | 510 | 5.1 |

| ST12F | 9 | Ultra-fine | 93.5 | 1960 | 14.4 | 5500 | 10 | 500 | 5.3 |

| ST12NF | 9 | Nano | 94.2 | 2100 | 14.3 | 5600 | 9 | 500 | 5.3 |

| ST15D | 9 | Submicron | 91.2 | 1520 | 14.4 | 4100 | 13 | 500 | 5.3 |

| ST15F | 10 | Submicron | 92.0 | 1670 | 14.3 | 4600 | 11 | 490 | 5.4 |

| ST20F | 10 | Submicron | 91.7 | 1620 | 14.4 | 4700 | 11 | 490 | 5.4 |

| ST20D | 10 | Submicron | 92.0 | 1670 | 14.3 | 4300 | 11 | 490 | 5.4 |

| ST25F | 12 | Ultra-fine | 92.4 | 1740 | 14.1 | 5100 | 10 | 470 | 5.7 |

| ST25EF | 12 | Ultra-fine | 92.2 | 1700 | 14.1 | 4700 | 10 | 470 | 5.7 |

| ST25D | 12 | Ultra-fine | 91.5 | 1570 | 14.2 | 4600 | 13 | 470 | 5.7 |

| ST37NF | 15 | Nano | 92.0 | 1670 | 13.8 | 5700 | 10 | 430 | 6.3 |

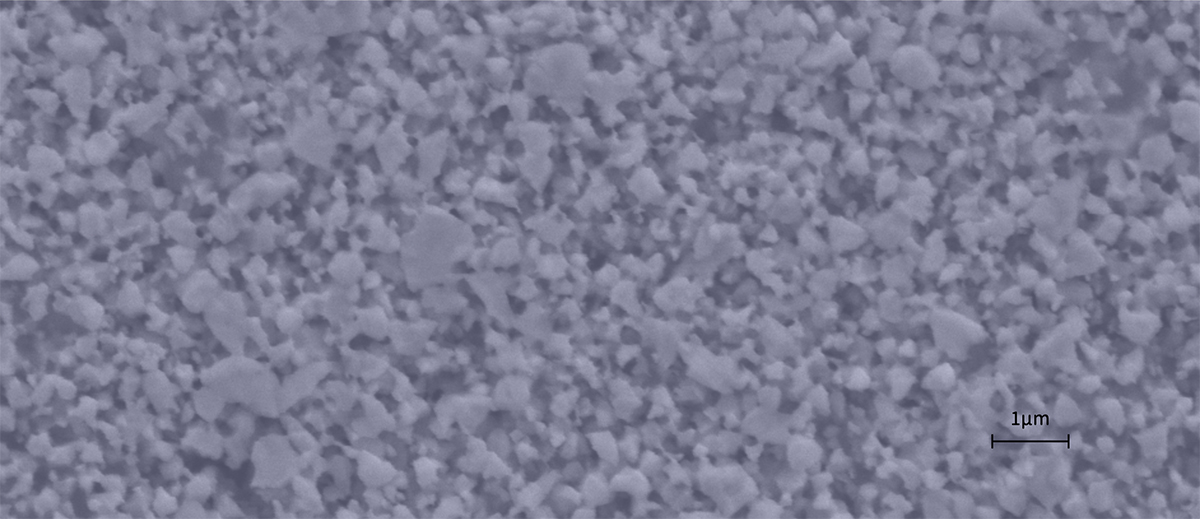

Electron Microscope Image of ST12NF Nano Cemented Carbide

| Recommendation Guide for Cemented Carbide Grades | |||||||||

| Workpiece Material | Machining Method | Grade | |||||||

| Carbon Steel, Alloy Steel, Cast Steel | Rough Milling | ST20F/ST11F | |||||||

| Carbon Steel, Alloy Steel, Cast Steel | Finish Milling | ST20F/ST25EF | |||||||

| Carbon Steel, Alloy Steel, Cast Steel | Drilling | ST15F/ST15D | |||||||

| Carbon Steel, Alloy Steel, Cast Steel | Reaming | ST11F/ST12F/ST25F | |||||||

| Cast Iron | Rough Milling | ST11F/ST20F | |||||||

| Cast Iron | Finish Milling | ST10F | |||||||

| Cast Iron | Drilling | ST20F/ST15F | |||||||

| Cast Iron | Reaming | ST11F | |||||||

| High-Hardness Steel | Rough Milling | ST12F/ST25F | |||||||

| High-Hardness Steel | Finish Milling | ST12F/ST12NF | |||||||

| High-Hardness Steel | Drilling | ST12F | |||||||

| Stainless Steel | Rough Milling | ST15D/ST25EF/ST25D | |||||||

| Stainless Steel | Finish Milling | ST25F/ST12F/ST15D/ST25D | |||||||

| Stainless Steel | Drilling | ST15F | |||||||

| Stainless Steel | Reaming | ST15F/ST11F | |||||||

| Titanium Alloy, Superalloy | Rough Milling | ST25EF/ST25F | |||||||

| Titanium Alloy, Superalloy | Finish Milling | ST25F/ST12F | |||||||

| Titanium Alloy, Superalloy | Drilling | ST15F | |||||||

| Titanium Alloy, Superalloy | Reaming | ST15F/ST25F/ST11F | |||||||

| Aluminum Alloy, Copper Alloy | Rough Milling | ST11F/ST10F | |||||||

| Aluminum Alloy, Copper Alloy | Finish Milling | ST10UF | |||||||

| Aluminum Alloy, Copper Alloy | Drilling | ST11F/ST15F | |||||||

| Aluminum Alloy, Copper Alloy | Reaming | ST11F | |||||||

| Plastic, Composite Material | Rough Milling | ST10UF/ST10NF | |||||||

| Plastic, Composite Material | Finish Milling | ST10UF/ST10NF/ST12NF | |||||||

| Plastic, Composite Material | Drilling | ST11F/ST15F/ST12NF | |||||||

| Diamond Coating | ST10C | ||||||||

Remarks:

The above are the recommended reference grades of our company for different materials. The specific performance parameters of each grade are shown in the attached table.

Since the tool geometry and coating have a significant impact on tool performance, the grade recommendations are for reference only.

Get Free Quotes

Please fill in your contact information (the information is confidential and will not be disclosed to the public), we will contact you as soon as possible.

Contact

Address:Contact

Tel:+86-190 6712 9860

Fax:+86-190 6712 9860

E-mail pm@csu-pm.com

Copyright © Hunan Boyun-Dongfang Powder Metallurgy Co., Ltd All Rights Reserved. Hunan ICP No. 2022013114-1