Mr. Huang Boyun

Mr. Huang Boyun

Academician of Chinese Academy of Engineering, Former President of Central South University

Honorary Chairman of PM

R & D Innovation Team :

Huang Boyun, male, Han Nationality, born in November 1945 in Nanxian County, Hunan Province, CPC member. He graduated from the Department of Special Metallurgy, Central South University of Mining and Metallurgy in 1969. He obtained a master's degree and a doctor's degree from Iowa State University in the United States from 1980 to 1986. He then entered the University of Tennessee and Oak Ridge National Laboratory in the United States to engage in post-doctoral research. He returned home in 1988. Professor Huang Boyun was elected as academician of Chinese Academy of Engineering in 1999, academician of Chinese Academy of Sciences in 2007, director of "10th Five-Year" National 863 Program Expert Committee on New Materials, president of South China University of Technology in 1997, president of South China University from 2001 to 2011, representative of the 16th and 17th National Congress of the Communist Party of China and member of the 11th National Committee of the Political Consultative Conference. He is currently a member of the Standing Committee of the 12th National People's Congress, Vice-Chairman of China Association for Science and Technology, Chairman of Hunan Association for Science and Technology, Chairman of China Society for Material Research and Professor of Central South University.

Established in 1994, the High Performance Carbide Innovation Team of Hunan Boyun Oriental Powder Metallurgy Co., Ltd. (hereinafter referred to as the "Innovation Team") led by Academician Huang Boyun is a high-level innovation team with Academician Huang as the chief scientist, including Chairman Li Yongxia, Deputy General Manager Zou Dan, Expert Zhou Jianhua, Deputy General Manager Cheng Xulin, Chief Engineer Fu Kun, Deputy President Xie Yuanyan and Expert Chang Yiming as core members.

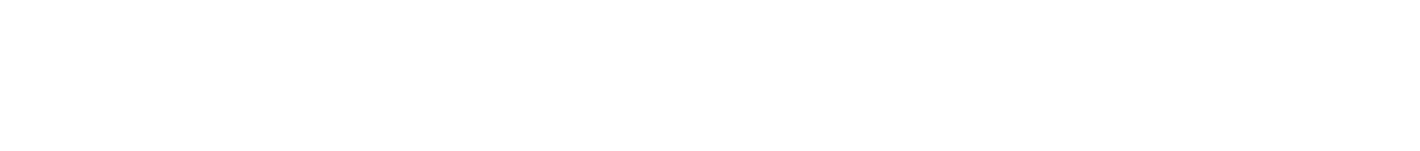

Innovation "is the core concept of business and development of Boyun Oriental. The innovation team of Boyun Dongfang focuses on the cutting-edge science and technology, aiming at the world's cutting-edge technologies of nanocrystalline and ultra-coarse crystal cemented carbide. The grain size of the self-developed nano cemented carbide WC is 0.11 μ m, which is one of the few enterprises producing and selling nano cemented carbide in batches in the world at present; In 2020, Boyun Dongfang will prepare super-coarse crystal cemented carbide with WC grain size more than 9 μ m with better performance, reaching the domestic leading level. Boyun Dongfang has been awarded 2 provincial and ministerial awards for scientific and technological progress, 27 national patents, and drafted 1 national standard. In 2021, it was identified as the "Little Giant" of national expertise and special new technology.

Top 1 Key Achievements: Strengthening the Chain, Supplying and Extending the Chain to Help Changsha Build a World-class Construction Machinery Industry Cluster

The industrial preparation technology of BOYON Dongfang High-performance super-coarse crystal hard alloy has reached the international advanced level as a whole, and the new process of preparing super-coarse crystal WC powder and the prestress control technology invented by the self-activation reduction - high temperature carbonization method have reached the international advanced level. The super-coarse crystal carbide shield cutter head developed by the innovation team is the key core component of the shield machine. The Project of Key Designing and Manufacturing Technology and Application of Cutting Head of Tunneling Machine and its Extra-coarse Crystal Carbide Cutter won the first prize of China Nonferrous Metals Industry Science and Technology Award; The Project of High-performance Cutter Material and Key Technology of Large Tunnel Boring Machine in Complex Stratum won the first prize of Sichuan Science and Technology Progress Award. This achievement has been successfully applied to the "Jinghua" shield machine with the largest diameter in China and the "Shenjiang 1" shield machine for the deepest submarine tunnel in China. It solves the "short board" problem of engineering machinery, promotes the independence, localization and localization of key materials and core components, and provides strong chain support for the "national key device" to lead the world.

Key Achievements Top 2: High-performance nano carbide cutter effectively solves the difficult machining problem of hardened steel for auto dies

High-end nano cemented carbide materials and tools independently developed by Boyun Dongfang with international competitiveness are used for machining hardened steel of automobile dies. Through use by users, the performance of this product is compared with that of international high-end brand friends, the comprehensive efficiency of this tool is improved by 45% - 50%, effectively solving the problem of difficult machining of hardened steel for auto dies. It has core competitiveness in domestic and international markets, and is a representative nano carbide tool product of "domestic substitution for import", helping to provide guarantee for the safety of the whole industry and the national supply chain.

Key achievement Top3: the international leading coating technology provides customers with comprehensive solutions

Boyun Dongfang PVD coating technology has the advantages of low deposition temperature, fast deposition rate, high coating hardness, good abrasion resistance, strong crack propagation resistance, no pollution to the environment, etc. It is widely used in aerospace, medical devices, electronic communication, automotive parts, mold manufacturing and other fields, and the domestic high-end market is mainly monopolized by foreign coating companies. On the basis of digesting and absorbing the world's advanced coating technology, the innovative team of Boyun Dongfang has successfully developed a new process of tool coating and provided customers with more professional solutions by tackling and re-innovating key problems and jointly tackling key problems with customers in terms of the tool coating, engine erosion resistant coating and thermal barrier coating technology of difficult materials such as superalloy composite materials for aerospace.

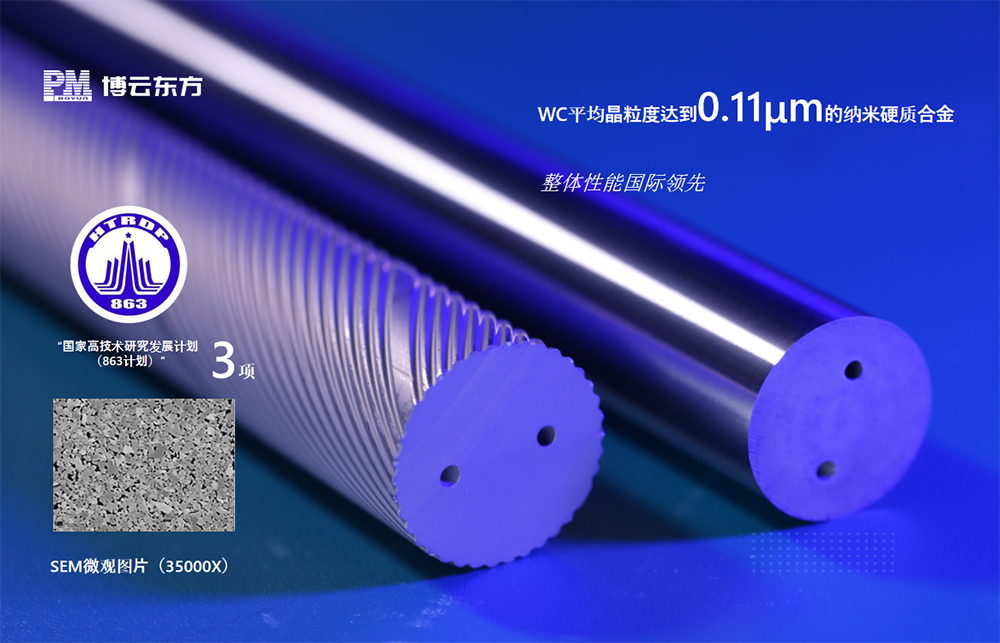

Boyun Dongfang mainly engages in high-performance superfine/nano cemented carbide bars, high-performance cemented carbide mold materials, high-performance super coarse-grained engineering and mining cemented carbide, fine and deep processed cemented carbide finished products (parts/components) and coatings, etc.

_1.jpg)